TPU film coating skills have those?

Date:2023-08-18

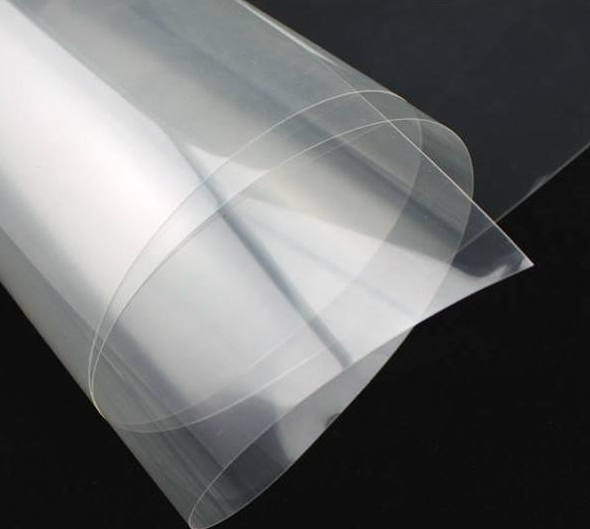

TPU film is made on the basis of TPU granules by special processes such as calendering, casting, blowing film and coating. Thickness 0, 01 to 2mm; TPU(Thermoplastic polyurethanes), a thermoplastic TPU elastomer, is made of MDI containing NCO functional group and POLYOL containing OH functional group, 1, 4BG, by mixing and mixing, because of good elasticity, good physical property and various mechanical strength are good, so, Widely used in injection, extrusion, calendering and dissolving into solution resin processing methods, is a plastic material often used by plastic processing companies, and its products cover the range of industrial applications and civil necessities.

In recent years, due to the continuous development of new products, the amount of thermoplastic PU elastomer is continuing to increase, creating a new opportunity for the plastic processing industry with low cost and high added value. TPU (thermoplastic polyurethane) is increasingly popular because of its superior performance and environmental protection concept. At present, wherever PVC is used, TPU can become a substitute for PVC.

But TPU has the advantages that PVC can't match. TPU not only has superior characteristics of high tension, high tension, toughness and aging resistance, but also is a mature environmental protection material. At present, TPU has been widely used in: footwear, clothing, inflatable toys, water and underwater sports equipment, fitness equipment, car seat materials, umbrellas, suitcases, bags, etc.

TPU film is made on the basis of TPU granule material by rolling, casting, blowing film, coating and other processes. At present, it is widely used in sports shoes: trademark decoration on sole and upper, air bag, air cushion, oil bag and so on. Today, there are two trends in the application of TPU film in sports shoes: First, the popular trend of blowing up by women's sandals, that is, the high transparent TPU film or direct cutting, or screen printing color, or the cloth base into a clip mesh cloth, etc., high frequency forming and bonding on the upper, with functional and decorative effects. The second is to use waterproof and moisture-permeable TPU film and shoe cloth to achieve waterproof and moisture-permeable effect.

The main features of TPU are:

1, a wide range of hardness: by changing the ratio of TPU reaction components, products with different hardness can be obtained, and with the increase of hardness, the product still maintains good elasticity and wear resistance. High mechanical strength: TPU products have outstanding bearing capacity, impact resistance and shock absorption performance.

2, outstanding cold resistance: the glass transition temperature of TPU is relatively low, and it still maintains good elasticity, flexibility and other physical properties at minus 35 degrees.

3, good processing performance: TPU can be processed by common thermoplastic material processing methods, such as injection molding, extrusion, calendering and so on. At the same time, TPU and some polymer materials can be processed together to obtain complementary polymer alloys. Resistant to oil, water and mold.

Use of various TPU molding products:

1, auto parts ball coupling; Dust cover; Pedal brake; Door lock firing pin; Bushing plate spring bushing; Bearings; Shock-proof components; Interior and exterior decorative parts; Anti-skid chains and other mechanical and industrial components

2, all kinds of gears; Seals (mainly wear and oil resistance); Shock-proof components; Drawing needle; Bushing; Bearing cover; Connector; Rubber screen; Printing roller and other clothing accessories women bra straps, clothing elastic, etc.

3, shoes softball shoes, baseball shoes, golf shoes, football shoes soles and shoes front shoe heels of women's shoes; Ski boots; Safety boots, other self-aligning wheels;