SGP ion intermediate membrane

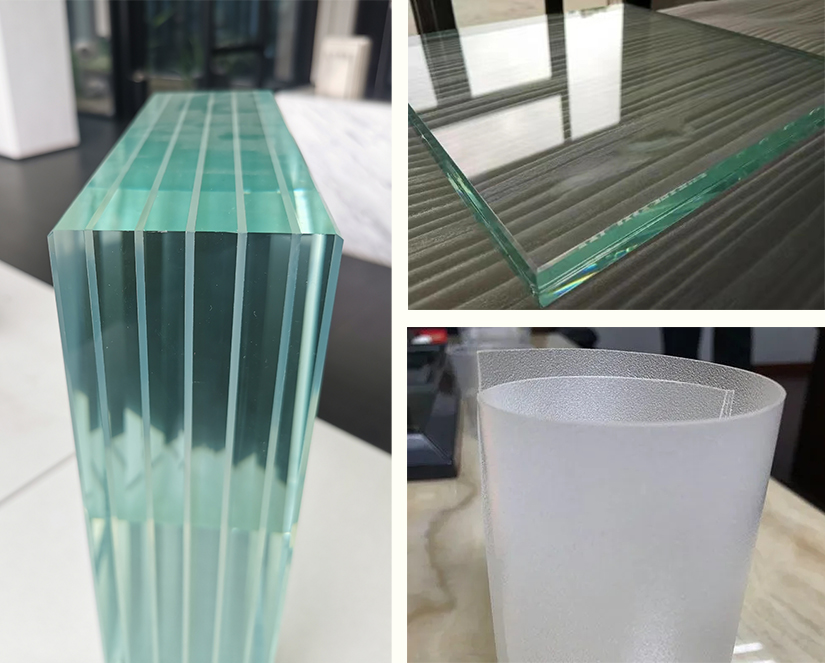

products detial

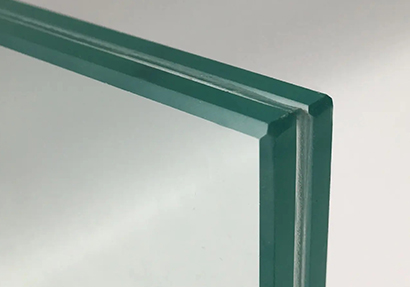

SGP intermediate membrane It is a new type of polymer material bonded by ionic bond, which has the characteristics of high polymer and high elastic modulus.

Advantages:

It has high strength and shear modulus

Good side stability, open side use

High strength safety and intrusion resistance after glass breakage

Colorless and transparent, not easy to change color, excellent permeability

Angu SGP film product Specifications (roll) | ||

| thickness | breadth | Length |

| 0.76mm | 800mm-3660mm | 200m |

| 0.89mm | 800mm-3660mm | 200m |

| 1.14mm | 800mm-3660mm | 150m |

| 1.52mm | 800mm-3660mm | 100m |

Note: Other non-standard sizes can be customized according to customer requirements | ||

Performance comparison between Angoo SGP film and ordinary PVB film | |||

| Material properties | Secure SGP | Common PVB | Test standard |

| Specific gravity g/cm | 0.95 | 1.066 | GB/T1033.1-2008 |

| Tensile strength MPA | 34.5 | 28.1 | GB/T1040.1-2018 |

| Tearing strength KN/M | >120 | 10-20 | GB/T1040.3-2006 |

| Elongation at break | 400% | 275% | GB/T1040.1-2018 |

| Fog degree | <1% | 2% | GB/T2680 |

| Yellow index | <1.5 | 6-12 | GB/T2680 |

| Refractive index | 1.5 | 1.47-1.5 | GB/T2680 |

| Light transmittance | 89% | 89% | GB/T2680 |

| Moisture content | <0.2% | 0.35%-0.65% | Ionic intermediate membrane cluster |

| Bonding force knock value | ≥7 | ≥6 | GB/32020-2015 |

| Residual strength after failure | <10.0cm | ╱ | Ionic intermediate membrane cluster |

【Product features and advantages】

It has high strength and shear modulus SGP has excellent mechanical properties, its shear modulus is 100 times that of PVB, and its tearing strength is 5 times higher than PVB. After glass SGP is laminated, the bearing capacity is twice that of PVB laminated glass of equal thickness. Under the same load and the same thickness, the bending deflection of SGP laminated glass is only 1/4 of that of PVB laminated glass. |

|

| High strength safety and intrusion resistance after glass breakage Ordinary PVB laminated glass, especially tempered laminated glass, once broken will produce a large bending deformation, there is a risk of falling off the whole piece. SGP intermediate film laminated glass has good integrity, even if the glass is broken, SGP film can bond the broken glass to form a strength structure after damage, so that its bending deformation is small, and it can withstand a certain amount of load without falling the whole piece. Greatly improve the safety of public areas in glass buildings. |

Good side stability, open side use Edge stability refers to the durability of the edge of laminated glass exposed to atmospheric conditions. PVB glue is easy to unglue and separate under the action of water vapor, and the exposed edge needs to be sealed. SGP film has good edge stability, is not sensitive to moisture, low hygroscopicity, will not be used under exposed conditions, can be used with open edge. |  |

| Colorless and transparent, not easy to change color, excellent permeability The SGP film itself is colorless and transparent, and has good weather resistance, and the yellowing coefficient is less than 1.5, while the yellowing coefficient of PVB film is 6~12. At the same time, SGP film still maintains its initial transparency after many years of use, and ordinary PVB intermediate film will gradually fade during use. |

Excellent weather resistance, not easy to age After years of aging tracking test by authoritative institutions, there is still no obvious bubble and yellowing phenomenon after 20 years. |  |

| Excellent adhesion to metal SGP has high bond strength with metals, such as aluminum, steel, and copper. The laminated glass made of SGP and metal wire, mesh and plate can greatly improve the performance of glass after breaking, and has strong anti-damage and anti-intrusion performance. |

【Product technology】

SGP film processing before cutting Before the SGP film is combined, the adhesive stick is used, the ionized clean air is blown, and the original glass is wiped with a dust-free cloth. Generally, it is not recommended to use a cleaning machine, but if the surface adsorbs too much stains, you must use a cleaning machine, you need to pay attention not to use cleaning agents, you can use deionized water with a temperature of not more than 38 ° C. Glass cleaned with deionized water has a higher bond with SGP film than glass cleaned with tap water. |

|

lamination The SGP material must be bonded directly to the tin side of the glass, i.e. the ATTA direction (glass air side - glass tin side /SGP film/glass tin side - glass air side). For glass structures where the tin surface cannot reach the film, such as laminated glass or non-float glass production, a bonding accelerator is required on the non-tin surface. The formula and use method of adhesive accelerator are detailed after sale. |  |

Roll compression Compared with PVB laminated glass, SGP film laminated glass roller exhaust selected temperature and roller pressure and speed, the roller pressure is basically the same, the roller heating temperature is low, the speed is slow, the mechanical parameters can be set as follows: Thermostat preheating → glass surface temperature 20-25℃, humidity about 25% → Zone 1 thermostat 100-110℃, the first roll press, the pressure is 0.20.5Mpa, the roll distance is less than the total thickness of glass about 1mm → Zone 2 thermostat 130-140°C→ Zone 3 thermostat 170-180°C→ second roll press, The pressure is 0.3-0.5MPa, and the roll distance is less than about 2mm of the total thickness of the glass. In the actual operation process, you can refer to the manual to adjust the parameters. |

|

Vacuum extraction For more than two layers of SGP film superimposed together sandwiched in the middle of the glass, multi-layer structure of the sandwich glass bay: will light to show the bay. The glass pin of the technical limit is not really built in the pre-pressing process, and the vacuum bag process should be used. The cold drawing time is generally not less than 7 minutes, and more than 10 minutes is the best |  |

Autoclave process It is a key process for laminated glass to enter the autoclave for high temperature and high pressure treatment, and controlling the temperature and pressure of the autoclave is an important factor to produce high quality SGP laminated glass. A. The distance between the laminated glass in the autoclave and the socket should not be too small, at least about 2m; The local pressure of the glass should be minimized, and the uneven pressure will lead to the uneven thickness of the SGP film during the heating process, forming light distortion. The Angle of the glass on the socket should not exceed 10 degrees. B. The holding temperature is controlled between 125-135 ° C, and the holding time of SGP film laminated glass is more than 60 minutes, and the holding time of laminated glass with a thickness of more than 16mm will be extended. The cooling rate of the autoclave is not less than 2.2°C/min, and the pressure is controlled at 12-24Mpa |

|